By 2030, water demand in India is expected to be twice the available supply. To meet the supply challenges, public and private sector facilities have ambitious plans for developing holistic water and wastewater treatment and distribution infrastructure.

Demand for high-end treatment technologies in India will grow. Several government initiatives, including the

- Atal Mission for Rejuvenation and Urban Transformation

- National Mission for Clean Ganga

- Jal Jeevan Mission

- Community Drinking Water Schemes

are pushing growth in the Indian water and wastewater treatment market.

Wastewater treatment and reuse are vital for addressing water scarcity in India. Currently, about 70% of generated wastewater remains untreated, leading to severe pollution in rivers and water bodies. The government has established over 1,000 sewage treatment plants (STPs) with a capacity of approximately 30 million cubic meters per day, focusing on upgrades through initiatives like the Namami Gange Programme.

Some Advanced Water Treatment Technologies like membrane bioreactors (MBR) and electrocoagulation are being deployed to enhance the efficiency of wastewater treatment, enabling higher rates of recycling and reuse.

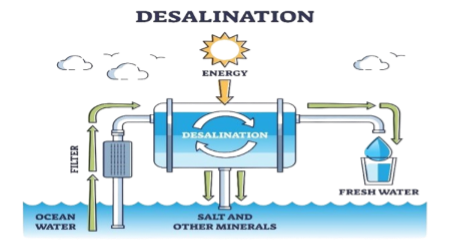

Desalination processes is a process of removing salts and other impurities from seawater to produce drinking water. This requires require significant energy. Building and maintaining desalination plants involve substantial investment.

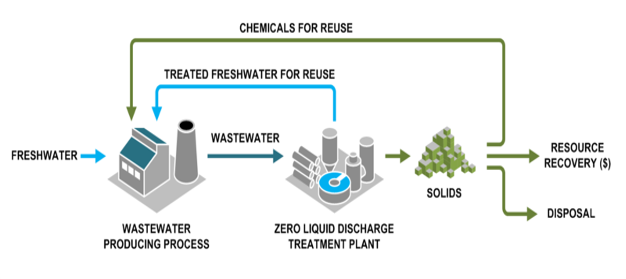

Zero Liquid Discharge- ZLD is a water treatment process aims to recover and reuse all water. ZLD systems are designed to minimize wastewater and produce clean water that is suitable for reuse.

Existing Scenario and Gaps-

- Limited Wastewater Treatment Facilities: Low availability and inadequate treatment facilities result in partial or untreated wastewater discharge, contributing to over 80% of surface water pollution in India (CPCB, 2007).

- Limited Sewage Coverage: Only 200 cities/towns in India have partial sewerage networks, with only 32.7% of the urban population (25.78 million of 78.9 million households) having access to sewer systems (Census, 2011).

- Insufficient Sewage Treatment Capacity: Current sewage treatment capacity in Class I and Class II cities covers only 30% of the total required treatment.

- Underutilized Treatment Capacity: Existing sewage treatment plants operate below potential, with an estimated capacity utilization of only 66%.

- Water Scarcity and Pollution Challenges: India faces challenges from decreasing per-capita water availability and increasing freshwater pollution, further intensified by economic growth.

- Urban Water Pressure: Urban areas are under immense water stress due to high water demands, exacerbated by urbanization.

- High Return Flow of Untreated Wastewater: Around 80% of municipal water supply returns to ecosystems as untreated wastewater, creating significant environmental and health risks.

- Gap in Sewage Treatment: Major cities generate an estimated 38,354 million litres per day (MLD) of sewage, but the existing treatment capacity is only 11,786 MLD.

- Industrial Wastewater Treatment: Only 60% of industrial wastewater, mainly from large-scale industries, is treated, leaving a substantial portion untreated and posing environmental risks.

Growth Drivers-

Namami Gange Programme –

Government has initiated 450 projects valued at ₹38,022.37 crore to restore the Ganga, covering wastewater treatment, solid waste management, riverfront development, afforestation, biodiversity conservation, and public participation.

Sewerage Infrastructure: 195 sewerage projects (₹31,344.13 crore) focus on creating and rehabilitating 6,173.12 MLD of sewage treatment capacity and 5,253.64 km of sewer networks to reduce river pollution.

Progress Achieved (31 Oct 2023): Of the 195 sewerage projects, 109 have been completed, adding 2,664.05 MLD in treatment capacity and 4,465.54 km of sewerage network.

The Water (Prevention and Control of Pollution) Amendment Bill, 2024

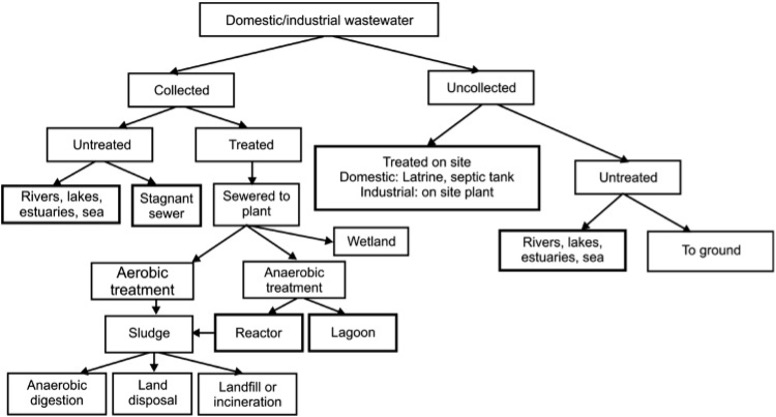

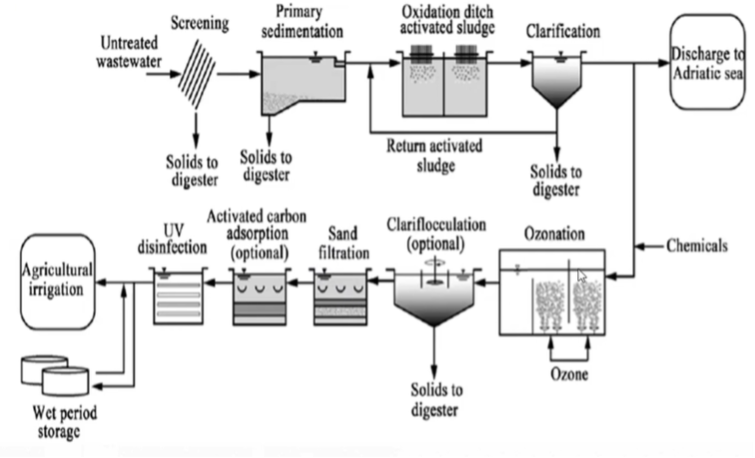

Flowchart of waste water treatment process

Source – https://www.sciencedirect.com/topics/earth-and-planetary-sciences/industrial-waste-water

Waste Water Treatment Process-

As in wastewater, industrial wastes also are treated by physical, chemical, and biological means.

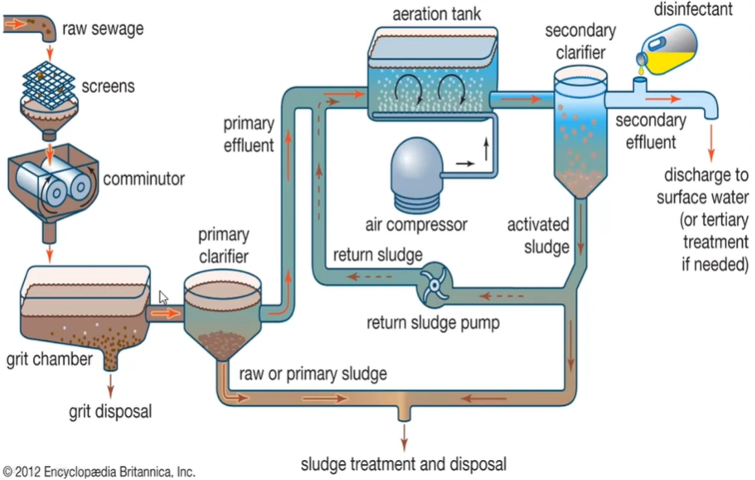

Process Flow-

Step-by-step flow of a sewage water treatment plant, covering each stage from raw sewage intake to treated water discharge and sludge management:

1. Preliminary Treatment

- Screening:

- Large screens filter out coarse solids, plastics, and other large debris.

- Prevents clogging and damage to downstream equipment.

- Grit Removal:

- Grit chambers remove sand, gravel, and other heavy particles.

- Protects equipment from abrasion and prevents accumulation in tanks.

2. Primary Treatment

- Primary Sedimentation:

- Wastewater flows into large sedimentation tanks where gravity settles solid organic matter (primary sludge) at the bottom.

- Grease and oils float to the top and are skimmed off.

3. Secondary Treatment (Biological Treatment)

- Aeration (Activated Sludge Process):

- Aeration tanks infuse oxygen to support aerobic bacteria that decompose dissolved organic matter.

- Microorganisms break down organic contaminants, forming a flocculent mass known as activated sludge.

- Secondary Clarification:

- The treated wastewater flows into a secondary clarifier, where the activated sludge settles at the bottom.

- A portion of this sludge is recirculated to the aeration tank (Return Activated Sludge, RAS), while the excess is removed as Waste Activated Sludge (WAS).

4. Tertiary Treatment (Advanced Treatment)

- Filtration:

- Treated water is filtered through sand or membrane filters to remove residual suspended solids.

- Disinfection:

- Disinfection (chlorination or UV treatment) kills pathogenic microorganisms.

- Ensures treated water meets quality standards before discharge or reuse.

5. Sludge Treatment

- Thickening:

- Collected sludge from primary and secondary treatment is thickened to reduce water content.

- Digestion:

- Anaerobic digestion breaks down organic material in sludge, reducing volume and odor while producing biogas as a byproduct.

- Dewatering:

- Dewatering presses or centrifuges further reduce sludge moisture content, making it easier to handle.

- Disposal/Recycling:

- Dried sludge can be disposed of in landfills, used as fertilizer, or incinerated.

6. Final Effluent Discharge

- Discharge to Environment or Reuse:

- The treated water, now free from harmful contaminants, is either discharged into rivers or reused for agriculture, landscaping, or industrial processes.

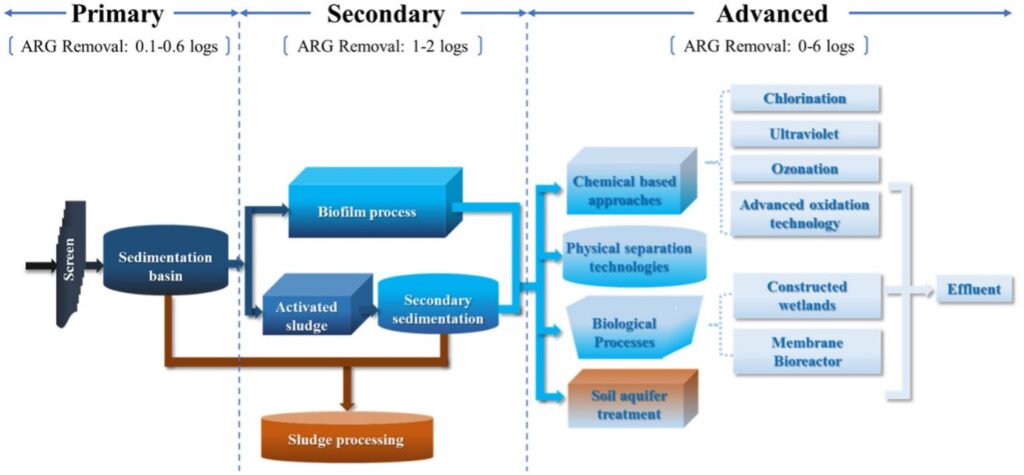

Different treatment of Wastewater

Source- https://www.sciencedirect.com/science/article/pii/S0160412019307378

To convert the above treated water for drinking purposes, we need to treat sewage water to drinking-water standards, an additional advanced purification stage is required after tertiary treatment. This stage typically involves a series of advanced processes, known collectively as potable reuse or advanced water purification. Here are the key additional steps:

1. Advanced Oxidation (optional)

Purpose: To further reduce organic contaminants, pharmaceuticals, and other micropollutants.

Process: A combination of ozone or hydrogen peroxide with UV light to create hydroxyl radicals, which are highly effective at breaking down complex organic molecules.

2. Membrane Filtration (Ultrafiltration or Nanofiltration)

Purpose: To remove remaining suspended solids, bacteria, and viruses.

Process: Ultrafiltration or nanofiltration membranes capture very fine particles, providing an extra barrier against pathogens and solids.

3. Reverse Osmosis (RO)

Purpose: Removes dissolved salts, heavy metals, and nearly all organic and inorganic contaminants.

Process: High-pressure filtration through a semipermeable membrane that allows water molecules to pass but retains contaminants.

4. Advanced Disinfection (UV Disinfection and/or Chlorination)

Purpose: Ensures any remaining pathogens are neutralized before distribution.

Process:

UV Disinfection: UV light kills any remaining bacteria, viruses, and protozoa.

Chlorination (for distribution stability): Ensures the water remains free of microbial contamination as it moves through the distribution system.

5. Mineral Reintroduction (Remineralization)

Purpose: To balance the pH and add essential minerals back into the water, enhancing taste and stability.

Process: After RO, water is often low in minerals, so calcium and magnesium may be added to achieve a balanced mineral composition suitable for drinking.

Case Study-

Tiger Bio Filter Sewage Treatment Plant at Vasantrao Bagul Udyan, Pune

Capacity: 500KLD || Investment Cost: Rs 1.25 Cr || O&M Cost: Rs 8.91 lakhs

Type of technology used: Bio-filtration technique, based on vermi-filtration, pressure sand filter and activated carbon filter was used in this project. The technique is environmentally friendly as it requires less operational land. The treatment system contains filter media with specially bred earthworms, which helps degrade organic waste from wastewater at a rapid rate. This helps in eliminating the need for forced aeration using a blower. The worms convert organic matter into valuable compost, which can be directly used as a fertilizer. The unique set-up of the treatment plant introduces a “trickling” action of the wastewater as it passes through the bio-media and dissolves oxygen into it. The inorganic waste in the water is removed by physical filtration and digested and metabolized by the earthworms and microorganisms. Treated wastewater is used in gardening, irrigation and construction sites.

Source – https://niua.in/c-cube/sites/all/themes/zap/assets/pdf/WATER%20MGT/WM3_WWRR.pdf

Value Chain of Water Treatment Process-

1. Role of EPC Players in Water Recycling in India

EPC (Engineering, Procurement, and Construction) companies manage end-to-end projects from designing plants to commissioning and maintaining them.

Notable Indian EPC players:

- Larsen & Toubro: Active in water infrastructure, especially for municipal sewage treatment plants (STPs).

- VA Tech Wabag: Specializes in designing, building, and operating water treatment plants.

- Thermax: Known for providing industrial water treatment solutions.

2. Preliminary Treatment

Screening

- Equipment: Coarse and fine screens, bar racks, and mechanically cleaned screens.

- Suppliers:

- Jash Engineering – Specializes in screening and rake bar systems.

- Andritz – Provides custom screening solutions.

Grit Removal

- Equipment: Grit chambers, grit classifiers, grit separators.

- Suppliers:

- Jash Engineering – Supplies grit removal systems.

3. Chemical Processes in Water Treatment

The chemical processes used in wastewater treatment ensure the removal of contaminants and make water reusable. Common processes include:

- Coagulation and Flocculation: Uses chemicals like aluminum sulfate or ferric chloride to aggregate particles.

- Sedimentation and Filtration: Involves filtration sheets for additional purification, often sourced from manufacturers like Ion Exchange (India) Ltd..

- Disinfection: With chemicals like chlorine or ozone to kill pathogens.

4. Manufacturers of Filtration Sheets and Chemicals in India

Several Indian companies manufacture essential components for water treatment:

- Filtration Media and Sheets:

- Ion Exchange (India) Ltd.: Supplies filtration media and specialized filtration systems.

- Thermax Ltd.: Provides filtration solutions tailored for industrial applications.

- Water Treatment Chemicals:

- Chembond Chemicals: Supplies coagulants, flocculants, and disinfectants.

- National Peroxide Ltd.: Major manufacturer of hydrogen peroxide, used for disinfection.

- Ion Exchange: Comprehensive range of resins, specialty chemicals, and customized chemical treatment programs for water, non-water, and specialty applications.

Capex requirements-

Capex for sewage water recycling in India involves substantial investment, including:

- Treatment Plants: Establishing a sewage treatment plant (STP) with advanced technologies like reverse osmosis and UV filtration. A typical plant treating 50 million liters per day (MLD) costs around ₹200-250 crore.

- Equipment: Includes pumps, filtration systems, and chemical dosing equipment, costing around ₹40-50 crore per plant for a 50 MLD capacity.

- Infrastructure: Laying pipelines for transporting and distributing treated water costs another ₹20-30 crore depending on distance and terrain.

For a large metropolitan STP setup, the total Capex can reach ₹300-350 crore.